I. Introduction: How to Achieve Safety And Portability?

In drone design, many manufacturers, in the pursuit of lightweight builds and reduced R&D costs, often end up compromising both safety and portability. For example, exposed propellers may reduce weight and improve efficiency, but they pose obvious safety risks.

Meanwhile, foldable structures, while convenient for storage, often add weight and structural complexity, significantly increasing design challenges.

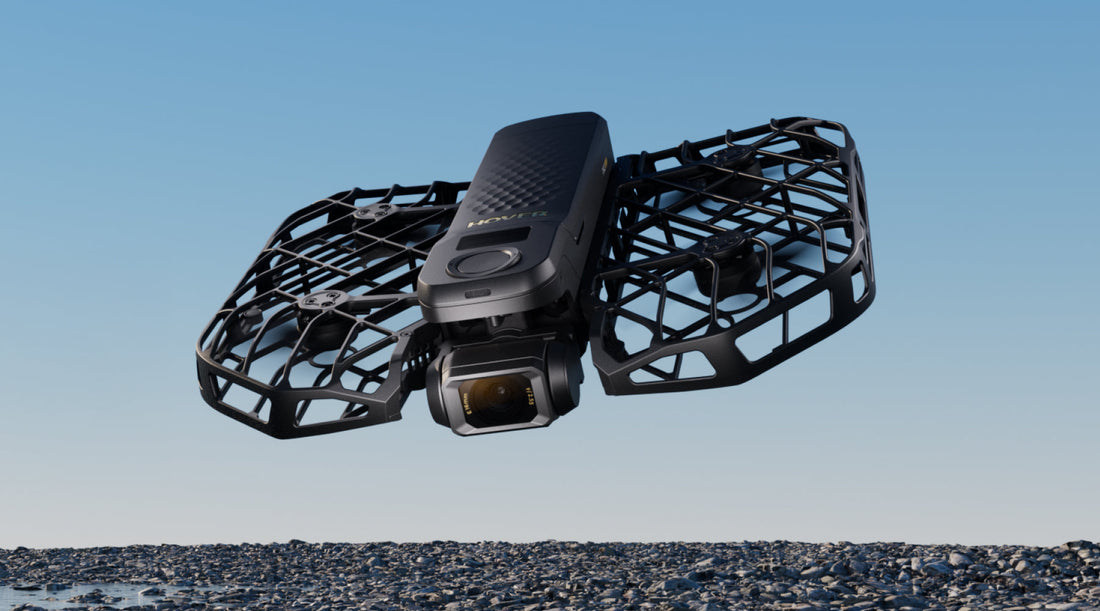

The HOVERAir X1 PRO / PROMAX, however, breaks through these industry trade-offs with an innovative approach, achieving an ideal balance of safety, portability, and lightweight performance:

- Fully enclosed body for safe, blade-free operation—even close-up handling is worry-free

- Foldable design for effortless storage and on-the-go portability

- Under 200g total weight, making it truly easy to carry everywhere

- All while maintaining stable flight performance and exceptional durability

These achievements are the result of breakthroughs in structural design, material selection, and system optimization, enabling HOVERAir to deliver a flight experience that is compact, high-performing, and reliably safe.

II. The Secret Behind the Fully Enclosed Design: Stability Without Compromising Efficiency

Patented Protective Grid Frame

The X1 PRO &PROMAX uses a patented precision-engineered grid frame to achieve the dual balance of safety and performance:

- High-strength protection: Full-body coverage shields the rotors, preventing accidental contact

- Minimized airflow loss: Unique grille angles and ventilation structure reduce intake turbulence, ensuring efficient and stable thrust

- Noise reduction optimization: Aerodynamic design paired with rotor tuning significantly lowers flight noise

Proprietary Four-Blade Short-Span Propellers + Precise Spacing

To fit the enclosed frame, the X1 PRO &PROMAX uses custom-designed four-blade short-span propellers:

- Increase airflow efficiency

- Reduce turbulence and vibration

- Maintain strong thrust and low noise in a compact space

III. Foldable but Durable: Structural Innovation and Reliability

Why Foldable Drones Are Rare

- Foldable designs impose high demands on strength and durability:

- Repeated folding/unfolding can cause structural fatigue

- Hinges are stress concentration points, prone to deformation or loosening

- Foldable structures often require extra small components, adding weight

- Increased mechanical complexity may amplify vibration, requiring extensive R&D

- High-flexibility materials are essential to maintain reliability

Most drone brands avoid foldable designs to reduce engineering complexity and R&D risk.

HOVERAir has always been committed to creating highly portable drones. We have devoted significant effort to overcoming these challenges, including the collaborative development of lightweight materials that are both high-strength and highly resilient. Additionally, we employ vibration-dampening balls combined with high-precision IMUs to effectively minimize vibrations, ensuring stable and smooth flight performance even in demanding conditions. Below is a detailed explanation of how this works.

HOVERAir Breakthrough: HEM+ High-Reliability Structural Design

The X1 series uses HEM+ high-toughness engineering materials, offering:

- Excellent impact resistance and fatigue resistance

- Stable toughness under extreme temperature variations

- Long-term foldable use without loosening or deformation

- Very lightweight — even lighter than carbon fiber

Strict reliability standards

From day 1, HOVERAir set strict reliability standards, including three rigorous tests for all prototypes:

- Six-Surface Corner Drop Test: Verifies resistance to impacts from all directions

- Rolling Drop Test: Simulates repeated accidental collisions

- Flight Impact Test: Checks structural stability after in-flight impacts

Through repeated testing and fine-tuning, HOVERAir ensures foldable structure stability, compactness, and durability, achieving “foldable, yet reliable and strong.”

-

Vibration Reduction: Dual System with Dampening Balls + IMU

To maintain stable and clear imaging in complex environments, HOVERAir employs a dual vibration reduction system combining mechanical dampening balls and high-precision IMU (Inertial Measurement Unit):

- Mechanical layer: High-elasticity dampening balls isolate high-frequency motor and arm vibrations from the camera module, significantly reducing mechanical interference with the image

- Algorithmic layer: The IMU monitors flight attitude and vibration data in real time, while intelligent algorithms dynamically compensate for micro-movements and jitters

- Collaborative optimization: Mechanical and algorithmic solutions work together to address both high-frequency micro-vibrations and sudden external disturbances

Thanks to this technology, the drone maintains stable, sharp footage during takeoff, hovering, or high-speed movement — reducing blur and providing a smoother visual experience.

IV. Dual Experience: Safety and Portability

- Safe and propeller-free: Fully enclosed design suitable for families and children

- Portable and convenient: Foldable for easy pocket or bag storage

- Efficient and stable: Low noise, strong thrust, long lifespan — balancing experience and performance

V. Conclusion: Comprehensive Upgrade from Structure to Experience

The HOVERAir X1 PRO &PROMAX redefines the standard for safe and portable drones with its innovative fully enclosed foldable structure:

“Lightweight and foldable, safe to touch, performance uncompromised.”